Béflex's New EFI VUTEk h Series Printer

- Publicado el 02 de Octubre de 2018

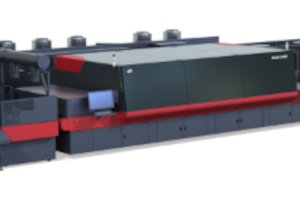

Budapest-based Béflex, a PoC (Point of Communication) print expert company, purchased the groundbreaking new EFI™ VUTEk® h3 hybrid flatbed/roll superwide-format printer from Electronics For Imaging, Inc. Béflex will be the first company to install the printer in Europe, allowing the company to further offer its customers innovative products with superior quality.

"We are constantly on the lookout for opportunities that allow us to provide our customers with the best products," said Lászlo Bárán, Béflex's CEO. "We are not interested in increasing volume unless we can provide brilliant quality, while maintaining constant production levels."

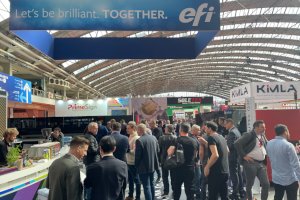

Béflex purchased its new printer at the FESPA tradeshow, where the VUTEk h series made its global debut. The h series is a next-generation, 3.2-metre hybrid roll/flatbed LED inkjet printer platform with a print resolution of up to 1,200 dpi, eight- or optional four-colour modes plus white, and up to five-layer print capability in a single pass. The newVUTEk h3 model prints up to 74 boards per hour.

The printer is a highly extensible platform as well, one that gives users the option of increasing throughput capabilities as needs demand. The VUTEk h3 model can be upgraded to a EFI VUTEk h5 model on site. With the upgrade, users can get even greater speed and capacity - up to 47% higher productivity with top print speeds of 109 boards per hour. Béflex is a long-time EFI VUTEk user, and the faster throughput and superior output quality of its latest VUTEk addition meets the company's two priorities: continuous development and advancement, and fulfilling customers' needs with the latest technologies.

The VUTEk h series comes equipped with a camera-based vision system for sub-pixel alignment, printhead density balance, and step and bi-directional setup, a feature that impressed Bárán. "The VUTEk h3's camera-based vision system for sub-pixel alignment is a significant feature, which is very important to improve quality and reliability," he said. The printer series features new, high-velocity UltraDrop™ Technology 7-picolitre greyscale printhead imaging for precision dot placement and consistency from print to print at high production speeds. The printer also offers mechanical crash and wrinkle detection and media height measurement for even greater printing accuracy and consistency.

The onboard diagnostics system on the printer will allow Béflex to continuously receive information on the state of the machine. "We've been told it will even help prevent problems. This will make in-house maintenance and service with minimal remote assistance a reality," said Bárán. "The built-in power monitoring and onboard diagnostics apply to a large number of issues - these can be remedied more quickly, ensuring continuous production." The VUTEk h series platform also is equipped with "ImageEdge" technology for fast and easy printhead replacement, and a new, modular drop-in ink delivery system design eliminates ink waste and provides fill-while-printing functionality for continuous productivity.

VUTEk h series LED printers can run high volumes on a broad range of rigid and flexible substrates up to 5.08 cm thick at full rated speeds thanks to features such as skip white and automated material handling options to meet nearly any production need. EFI VUTEk h series printers also have a significantly improved user interface with touch-screen control monitors on both the input and delivery sides. The printers are part of a complete, integrated system available only from EFI for world-class production workflow automation and production management. The latest-version EFI Fiery® proServer Premium digital front end (DFE) used with the printers combines faster RIPing with enhanced colour management and screening features.