Two innovation leaders cooperate to take an important step towards further digitization of the workflow with the IoT system RUBY

- Publicado el 08 de Febrero de 2023

Lengerich-based machine builder Windmöller & Hölscher (W&H), a manufacturer of machines for the flexible packaging market, and theurer.com, the leading provider of ERP/MIS software for the printing and packaging industry, will be going their separate ways in the future as part of W&H's RUBY product.

RUBY is the IoT system for optimizing packaging production with regard to the digitalization of the value chain. By intelligently improving parameters, higher productivity and better quality are achieved. Thanks to data-based error detection and alarms in real time, packaging production also becomes more efficient.

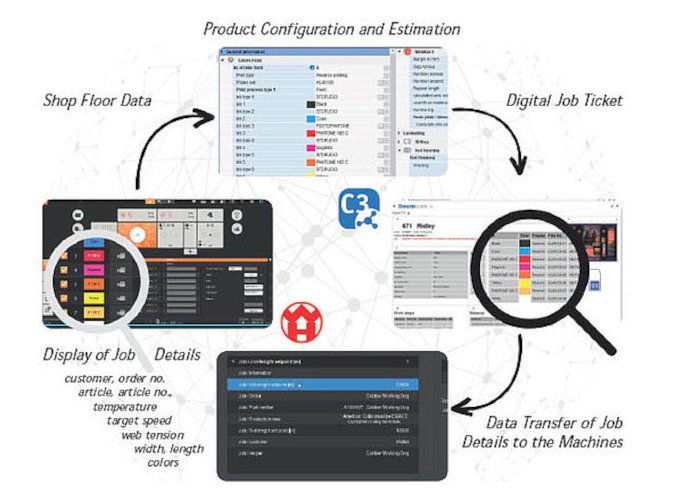

At the heart of the cooperation is a plug-and-play concept for the new RUBY Connect 4 Flow connectivity module, which digitizes the manual order process at the machine. This enables W&H machines, initially limited to the printing and extrusion sectors, to be networked with theurer.com's C3 ERP/MIS software via RUBY.

The aim is to create a standardized solution both for the digital transfer from C3 to the W&H systems and from the W&H systems back to C3. This means that job data and machine settings, as well as production feedback, are transmitted digitally. This enables the press specialists to prepare the job with all relevant press parameters such as temperatures, web tensions, etc. from the comfort of their office. This data is then sent digitally to the job level of the various presses. Once there, all that is needed is to select the next job from the list and all the press parameters are set at the touch of a button.

The cooperation brings great added value for both W&H and theurer.com customers. There is less integration effort during installation, the level of automation can be directly increased and human error settings can be reduced. "We are pleased to create new benefits for our customers. Through the cooperation, RUBY will be networked even more efficiently. This saves time, avoids errors and ensures maximum transparency as well as production control," says Stefan Brinkmeier, Product Manager for Connect 4 Flow at W&H. Tobias Theurer, Managing Director of theurer.com, also sees the cooperation as an important contribution to the digitization of processes: "The automatic and bidirectional transmission of job data creates a closed loop in the sense of an Industry 4.0 specific to the printing and packaging industry."

The concept was already presented at the EXPO, W&H's in-house exhibition, in October 2022 and met with great interest from customers. The interface and data architectures are currently being coordinated and programmed. With C3 as the leading software for the printing and packaging industry, theurer.com offers its customers many advantages: From the digital production order via MDE/DMI to the transmission of orders to the machines and now the connection to RUBY. Nevertheless, RUBY remains an open system that can be networked with other ERP systems in addition to C3.